We bring the technology

Complete lines for treatment, crashing, drying, transport and mixing of material

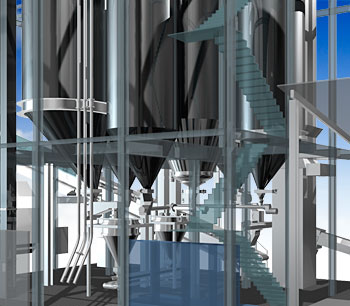

Are you considering to build, reconstruct or modernise your batch plant, sand plant or weighing system? Our technicians, experienced in processing, treatment and handling of material prior its feeding in the furnace, are ready to design the best possible solution for your production requirements.

All-inclusive supply of cullet management

Are you worried about the low condition of your cullet management and are you aware something has to be done about it? Do not hesitate and rely on the professionals with high experience in this field! Do not forget that cullet ranks among the most important batch ingredients and its quality and correct treatment effects the quality of final products.

All-inclusive supply of manual glass grinding and cutting

We can design and supply you with both individual machines and complete refinery lines for initial processing of intermediate products (cracking-off, cutting-off, melting-off), glass decoration (patterned or flat) and glass polishing (mechanical or chemical).

All-inclusive supply of chemical glass polishing plants

A drum-type polishing plant LZP is designed for polishing of all kinds of glass, especially lead crystal. It is the most common glass polishing system used in the Czech glassworks. The polishing process takes place in the drum that is equipped with removable cases filled with products. The drum rotates, so that the products are alternately soaked in the polishing baths (H2SO4 and HF)and the washing bath. An exhaust system for chemical gasses, equipped with an absorber, and a waste water neutralisation plant make inseparable parts of the polishing plant. All the polishing process is controlled by the central PC-control and the service control board. The programmes can be created according to customer's wishes. The parts coming to contact with corrosive environment are mostly made of suitable resistant plastics.