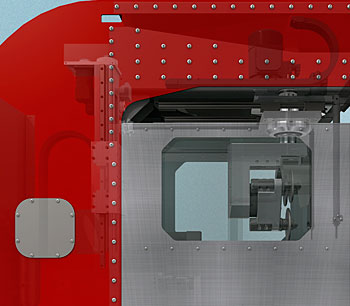

BM JACK 1: Glass cutting automat

BM-Jack 1 is designed for decoration of glass articles

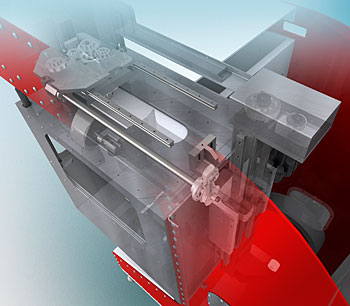

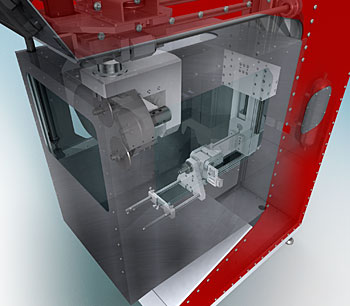

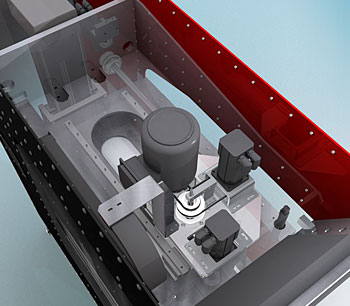

In fact, this machine brings a brand new innovation in glass cutting decoration. So far, the machine glass cutting has never been so close to the manual glass cutting decoration. The individual machine axes can move with servomotors. In total, there are seven servomotors mounted in the machine. The cutting wheel is driven with an asynchronous motor. An electric switchboard with all necessary electric components used to control the machine is a part of the machine too.

There is a touch-screen on the front side of the machine at which you can adjust some parameters necessary to tune up the cutting program.

The cutting program uses a design software. You can get this software in the following way:

- Purchase from Horus

- File generation according to customer’s wishes - this is convenient in the case of repeated orders

- Upgrading of an older Horus or Wincut program

The design software generates a data file that is subsequently loaded in the machine PC (situated in the machine switchboard). The machine computer repeatedly controls the whole cutting process then.

When cutting with more machines, just one design software is sufficient. It generates the data files for individual machines, e.g. different patterns can be cut at each position. This automatic machine is economical for as small batch as 60 - 100 article pieces.

The data files can be loaded from the design software using the following way – network data transfer, flash disc, CD, DVD or wireless data transfer.

The whole machine space demand does not exceed that of a single glasscutter. The machine is equipped with a closed cooling water circuit and water consumption is about 1000 litres a month. After adjustment, even an unqualified person can operate the machine. However, adjustment of the machine and the program maintenance should be performed by a qualified person and our company is ready to provide the training for your personal.